UConn’s Climate Action Plan (CAP) has led to the implementation of several notable projects and initiatives. The CAP outlines plans to improve sustainability under the following categories: transportation, energy, and sustainable development. In Spring 2012, UConn added an adaptation section to work in conjunction with its mitigation strategies. This section is focused on UConn’s research, outreach and service roles, as we seek to provide resources for improving the climate resiliency of communities throughout the state and region. The mitigation strategies in UConn’s CAP serve to identify the emissions reduction benefits and cost effectiveness of potential action items. The Office of Environmental Policy’s current emissions targets call for a 20% decrease in emissions by 2020 and 30% by 2025. UConn’s overall progression includes:

- Class III Renewable Energy Credits (RECs) generated by UConn’s Co-Generation Facility, sold to finance energy efficiency projects across campus

- 134 re-lamping projects completed for more than $700,000 per year savings in energy costs and over 5,000 Tons eCO2 avoided

- 19 retro-commissioning projects completed for $2.2 million per year savings in energy costs and more than 12,000 Tons eCO2 avoided

- LEED Silver certification requirement for all new building and renovations over $5 million

- Several variable-frequency drive (VFD) projects optimizing heating and cooling in buildings for around 1,000 Tons eCO2 avoided

- Long-term electricity purchasing agreement with ConEd for 40% of purchased electricity comprised of renewable energy

- Over 15% decrease in water consumption, despite 23% growth in user population from 2005-2014

- Agricultural/organic waste composting facility operating at maximum load of 800 tons per year

- Connecticut Institute for Resiliency and Climate Adaptation (CIRCA) established in January 2014

- 400 kW fuel cell and 7 kW solar array, providing electricity, heating, and cooling to the Depot campus

- 8 kW solar array on top of the reclaimed water facility

- Department of Energy’s Workplace Charging Challenge pledge signed: 5 active EV charging stations and an expanding EV fleet

- Transportation fleet now includes 15 hybrid vehicles and 12 plug-in EVs, including the EStar campus van (15% of the light-duty fleet)

UConn is still on track to meet its 20% interim reduction goal by 2020. This is being achieved primarily through on-going LED re-lamping projects in buildings, parking lots, and walkways, and with the replacement of old, inefficient steam pipes. These projects are expected to be completed between 2015 and 2020 and will yield an annual 13,265 ton reduction in carbon dioxide emissions. With all of these developments, UConn continues to strive toward carbon neutrality and a reduction of greenhouse gas emissions in the years to come. UConn’s Office of Environmental Policy uses the University of New Hampshire Campus Carbon Calculator (CCC) to store and track greenhouse gas information.

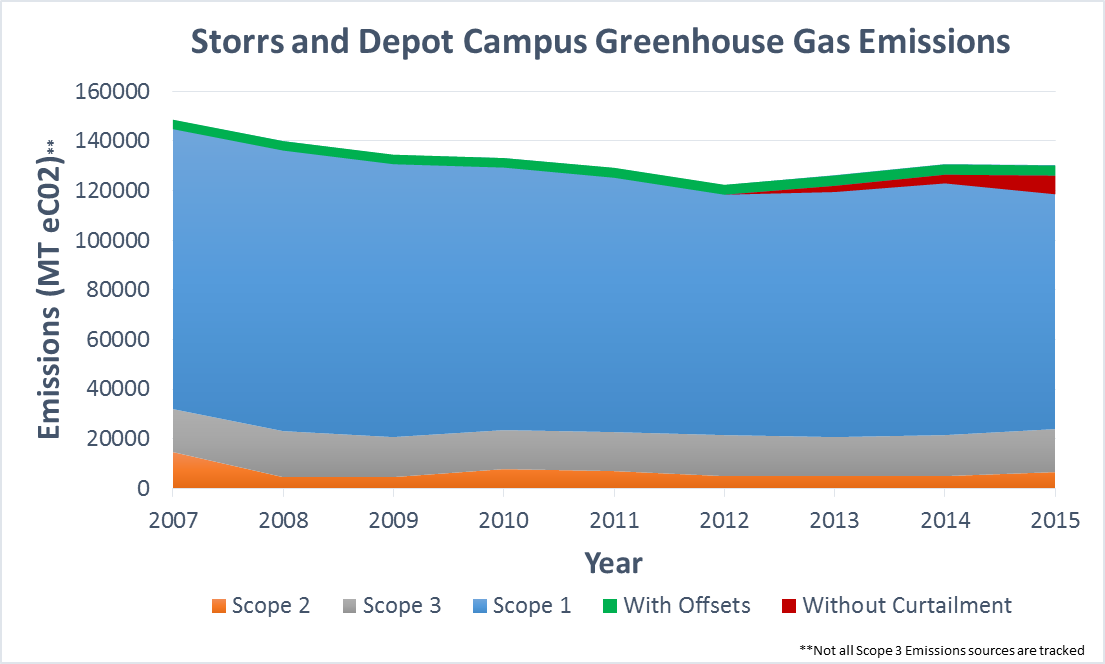

Electricity, heating, ventilation and air conditioning for buildings account for over 80% of the university’s carbon footprint based on current calculations which do not fully account for scope 3 emissions. As it can be seen above, a 12.9% decrease since 2007 is observed when the effects of natural gas curtailment are included. Curtailment occurs when the weather is especially cold and demand on the natural gas pipeline is high. This forces UConn to burn fuel oil instead of natural gas. On average, each day of natural gas curtailment results in 50,000 gallons of oil being consumed by the co-generation plant (a net release of 250 tons eCO2 per day*).

When natural gas curtailment is ignored, an 18.1% decrease in eCO2 emissions since 2007 is observed. It can be noted that the direct emissions sources from the university are decreasing, but with more cold weather affecting the local area, the amount of curtailment days has continued to increase. In the winter months of 2015, there were 30 days of natural gas curtailment, compared to 14 the prior year, and only 3 in 2012. Fortunately, the natural gas infrastructure in Connecticut is being expanded, so it is likely that we will not have further curtailment days next winter.

In addition, new building construction has accounted for a majority of Direct Source Emissions increase in recent years. A breakdown of UConn’s emission sources can be seen below.

*In recent years, each day of natural gas curtailment was estimated at an extra 500 tons of eCO2 per day. This has been adjusted to 250 tons of eCO2 per day based on conversations with compliance staff.