Paragraph explaining the contents of the page, etc.

Energy Efficiency

UConn’s Climate Action Plan (CAP), adopted in 2010, is aimed at mitigating the carbon footprint of the University. The CAP established a goal of achieving a carbon neutral main campus by 2050, with several interim milestones, such as a 20% reduction in greenhouse gas (GHG) emissions (from a 2007 baseline year) by 2020 and 30% by 2025. We work collaboratively with the Utility Operations & Energy Management group in Facilities to achieve these goals, primarily through a variety of strategic energy conservation projects.

The University is well on its way toward meeting these GHG emissions reduction goals. As of 2017, a net reduction of 18,882 tons of GHG emissions from the 2007 baseline had already been achieved. Current estimates indicate that by 2020, emissions will be reduced by another 20,108 tons. Accounting for ongoing and proposed energy efficiency and clean energy projects, UConn is on pace to reduce annual emissions by a grand total of 32,600 tons by 2020. This represents a 21.4% reduction, saving almost 38 million kWh worth approximately $2.9M, despite considerable growth in enrollment and new buildings constructed since 2007.

Two especially impactful initiatives include the campus-wide re-lamping and steam line improvement projects. Project evaluation estimates show that retrofitting all interior and exterior lighting with LEDs will contribute nearly 40% of the carbon emissions reductions needed to meet the 2020 interim goal, with ongoing steam projects contributing 30%. Another 19% reduction will come from ESCO Phase I. Completed in 2017, this is an approximately 2,600 linear foot steam line replacement project, with associated energy conservation measures (ECMs) in seven campus buildings. In total, ESCO Phase I saves the University a projected $1.3M each year in utility costs.

Additional energy efficiency and GHG reduction projects underway include increasing the percentage of green (EV and hybrid) vehicles in UConn’s fleet and implementing other ECMs, such as the installation of variable frequency drives (VFDs) on motorized equipment that controls HVAC systems.

UConn’s 2020 Vision Plan includes energy efficiency-related metrics, like completing the SLED project by 2020 and reducing Energy Use Intensity (EUI) by 20% in buildings served by the Central Utility Plant.

LEED Buildings

In 2016, the University adopted a new Sustainable Design and Construction Policy, stating that the University of Connecticut shall plan, design, construct, renovate and maintain sustainable, energy and water-efficient buildings.

All new construction projects at UConn estimated at greater than $5 million must pursue at least a LEED Gold rating.

The U.S. Green Building Council's LEED® rating system is the preeminent program for the design, construction, maintenance and operation of high-performance sustainable buildings.

Projects pursuing LEED certification earn points for various green building strategies across several categories. Based on the number of points achieved, a project earns one of four rating levels: Certified, Silver, Gold or Platinum.

Renewable Energy Strategic Plan

In Spring 2011, the Office of Sustainability (formerly Office of Environmental Policy), collaborating with the School of Engineering and the Center for Clean Energy Engineering, engaged consultants from CT’s Center for Advanced Technology to begin a preliminary siting and feasibility study for installing various forms of on-campus renewable/sustainable energy generation. The process began with a survey of faculty members identified as having research interests in alternative energy and fuels. Respondents were then interviewed about their work, in order to identify likely candidates for creating demonstration and/or working-scale projects to showcase their work on the University grounds. Investigators working on geothermal, solar thermal, solar PV, wind turbine efficiency, fuel cells, biofuel, biomass, micro-grids, and smart building systems, were interviewed.

In addition to the interviews, and during the course of developing the Renewable Energy Strategic Plan, UConn convened two meetings of faculty and operational staff in order to update participants on progress with the plan and to:

In addition to the interviews, and during the course of developing the Renewable Energy Strategic Plan, UConn convened two meetings of faculty and operational staff in order to update participants on progress with the plan and to:

- Ensure the alignment of academic and operational goals

- Encourage staff who occupy and manage potentially suitable host facilities to come forward

- Promote faculty grant applications for demonstration-scale renewable installations

- Identify and apply for other state and federal incentives

The Preliminary Feasibility Study and Strategic Deployment Plan for Renewable & Sustainable Energy Projects.pdf identifies and assesses target locations for the development of 12 demonstration-scale renewable and sustainable energy projects for the following technologies: solar thermal, solar photovoltaic, wind, fuel cells, geothermal, and biofuels. The development of renewable and sustainable energy projects at the University of Connecticut at Storrs will facilitate:

- Technology transfer

- Collaborative research into green energy sources and smart storage

- Reduce carbon dioxide (CO2) and other greenhouse gases (GHG)

- Integrate environmental principles into the student’s learning experience

These clean and renewable energy technologies will reduce GHG emissions by displacing emissions associated with the use of fossil fuels for electric generation, thermal energy, and/or transportation. The deployment of renewable and sustainable energy technologies identified in this Plan is consistent with the implementation of The University of Connecticut Climate Action Plan. Furthermore, this Plan compliments and expands upon the potential development opportunities for renewable and sustainable energy technologies identified within the Preliminary Feasibility Study and Strategic Plan for the Depot Campus.

Green Cleaning

Green Cleaning is defined as cleaning to protect health without harming the environment. Green cleaning is a widely accepted movement that uses procedures and products to make cleaning for the health of building occupants, janitors, and the environment a primary concern.

Some widely used cleaning products have serious adverse effects on the health of building occupants and janitors. Both long term and short term health effects are linked commonly to poor air quality as a result of clean product fumes.

As a result, the State of Connecticut and the University are committed to improving air quality and reducing hazard related to cleaning products, by using "green" cleaning products. These products are characterized by such qualities as biodegradability, low toxicity, low volatile organic compound (VOC) content, reduced packaging, and low life cycle energy use.

Why the need for green cleaning? Source: US EPA

One source of indoor air pollution can be found in the cleaning products used in the area. These products may produce noxious fumes or leave potent residues behind. Short term health problems caused by exposure to hazardous cleaning products include eye irritation, coughing, chest pain, vomiting, cramps, and diarrhea. Still worse are the long term effects, which may include liver and kidney failure, birth defects, emphysema, brain damage, and even cancer. Unintentional ingestion of toxic household chemicals in the U.S. costs almost $2.3 billion in health care per year.

In addition to being harmful to human health, many cleaning products have also proven harmful to the environment. Some of the more potent cleaners contain volatile organic compounds, phenolic compounds, or petroleum solvents and very few are biodegradable. Chemical cleaners produce 30,948 tons of hazardous waste each year and some ingredients of cleaning products are associated with eutrophication of streams and are toxic to aquatic organisms.

Why at the University of Connecticut?

Daily and periodic janitorial cleaning is commonplace at every UConn campus due to the large mass of traffic from the university community. As a result, the University of Connecticut is a large consumer of cleaning products. Therefore, we are working to encourage the use of green cleaners not only to promote clean and safe working conditions but also to reduce the impact on the environment.

The University of Connecticut is also required to comply with former Governor Rell's Executive Order #14. On April 17, 2006, Connecticut Governor Jodi Rell issued an executive order which declares that all state facilities and workplaces shall "procure and use, whenever practicable, cleaning and/or sanitizing products having properties that minimize potential impacts to human health and the environment, consistent with maintaining clean and sanitary State facilities."

Furthermore, on June 11, 2007, the Connecticut Legislature approved Public Act 07-100. This act mandates that cleaning products used in State buildings must meet environmental standards set by an approved environmental certification program. These products must seek to minimize their potential harmful impact on human health or the environment.

Co-Generation Plant

UConn’s state-of-the-art Co-Generation Facility opened in February 2006, replacing several oil-fired utility boilers and enabling the University to meet its own energy needs at the main campus.

Co-Generation is defined as the sequential production of both electrical or mechanical energy and useful thermal energy from a single energy source. This allows over 80% of the fuel energy to be harnessed, versus 33% from a conventional electric power plant. The Co-Generation facility provides a two-fold reduction in emissions:

- Natural gas, a cleaner burning fuel, is used by the facility to generate electricity and steam for heating and evaporative cooling.

- Also, the inclusion of steam production in the process removes the need to construct separate steam-production facilities that would burn their own fuel and have their own emissions.

Most power plants on the electric grid are considerably less efficient than cogeneration facilities because they do not capture and utilize the steam for heating and cooling. Also, “distributed generation,” like UConn’s 25 MW Co-Generation facility, prevents the efficiency loss and congestion that occurs during transmission and distribution of electricity from the point of generation to distant electricity customers.

Due to these features, the UConn Co-Generation facility reduces carbon dioxide (greenhouse gas) emissions by an estimated 30,000 tons each year versus emissions from fossil-fueled power plants serving the regional electric grid.

Alternative Energy Sources

The University of Connecticut commissioned a fuel cell power plant on its Depot Campus in April, 2012, that will supply the campus with clean and efficient energy, cooling, and heating for years to come. The installation of a UTC Power PureCell system is one of many steps made by UConn to reduce its carbon footprint and build a sustainable community. The fuel cell installation was made possible through a federal stimulus grant from Connecticut's Clean Energy Finance and Investment Authority.

The 400kW fuel cell will provide energy to UConn's research labs and offices, including those working on advancing fuel cell and microgrid technology at UConn's Center for Clean Energy Engineering. The PureCell system is an energy delivery solution that combines hydrogen fuel and oxygen from the air electrochemically (without combustion) to produce electricity, heat, and water. The new power plant will serve as a demonstration model and teaching tool for UConn students, helping them better understand the technology and benefits behind advanced microgrid energy systems that can deliver clean, reliable energy while protecting the environment.

By generating and using power on-site with a PureCell system, UConn will prevent the release of more than 831 metric tons of carbon dioxide annually, which is the equivalent to planting more than 192 acres of trees. The reduction in nitrogen oxide emissions compared to a conventional power plant is equal to the environmental benefit of removing more than 110 cars from the road. In addition to the reduction in greenhouse gas emissions, the PureCell system saves nearly 3.9 million gallons of water each year.

Click here to read the full article about the Fuel Cell from UConn Today.

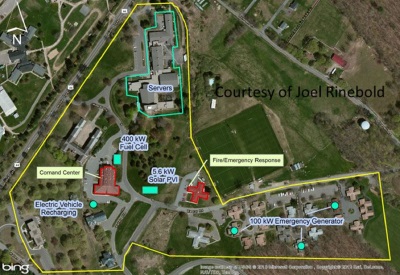

UConn is currently pursuing the creation of a Microgrid on Depot campus. The plan is currently undergoing the approval process and the technical feasibility evaluation was recently passed.pdf by the Department of Energy and Environmental Protection. The Microgrid proposal has also been given the formal support.pdf of the Town of Mansfield. In addition, the University of Connecticut was awarded a $2.14 million dollar grant as part of the Connecticut Department of Energy and Environmental Protection $18 million dollar Microgrid Pilot Program. This program was designed to research and document the effectiveness of microgrid energy systems in supporting and protecting critical needs systems during times of extended grid outages.

With the implementation of the new microgrid system, the fuel cell would be able to function at full capacity even despite the grid outage. This will allow the University’s critical needs facilities (fire/emergency response, command center, data servers, etc.) to keep functioning when they are needed most. Overall this project will bolster the university’s emergency response capabilities while providing significant research benefits on the practicality and effectiveness of microgrid systems for the state of Connecticut. Beyond emergency response, the microgrid will harden UConn's energy infrastructure, modernize the state’s electric grid, promote renewable energy projects, and support energy efficiency in the state of Connecticut.

Click here to read about Microgrid Progress and Emergency Response from UConn Today.