Climate and Energy

A commitment to positive change

The University of Connecticut is a signatory to the American College and University Presidents' Climate Commitment (PCC), which means that the University is striving towards a carbon neutral campus by the year 2050. The bulk of our climate initiatives can be found in our Climate Action Plan (CAP) below. The CAP currently focuses on strategies for reducing greenhouse gas emissions from the University. Our progress is being tracked through an annual greenhouse gas inventory. In 2012, an additional section to the CAP was written to include mitigation and adaptation strategies for the University. These two kinds of strategies will prepare the University for whatever effects of climate change we see. The CAP was created through the efforts of five Climate Action Task Forces (CATFs). A new task force known as the Climate Change Adaptation Task Force (CCATF) was created in 2011 to update the CAP.

Click here to view UConn's 2020 Vision for Campus Sustainability & Climate Leadership.

Climate Action Plan

The 2015 Interim Assessment of UConn's Climate Action Plan summarizes background information related to UConn's Climate Action Plan (CAP) commitment to a carbon‐neutral campus and reviews progress made since the CAP was approved in 2010 and reaffirmed by President Herbst in 2012. The assessment uses data derived from past experience to estimate greenhouse gas (GHG) emissions/reductions to be achieved from ongoing and potential projects. Energy models and emissions factors were also used to estimate anticipated GHG increases from planned capital improvements and the addition of fuel‐burning equipment. If reliable cost data is available for projects, it is cited in order to recommend the most effective ways to meet or exceed our interim carbon reduction goals.

Loading...

Loading...

The UConn Office of Sustainability performs an audit every year to determine our annual Greenhouse Gas (GHG) Inventory. The data from this inventory is used in annual reporting for AASHE Stars Reporting, Sierra Club Cool Schools, and Second Nature President's Carbon Commitment. A team of OS interns compiles data provided by many sources within UConn, including Facilities Operations, and uses the University of New Hampshire SIMAP Calculator to store and track greenhouse gas information. The OS has been completing the UConn GHG inventory for more than ten years, starting in 2010. Learn more about the three scopes of the GHG inventory below.

Scope 1: Direct Energy Usage

Scope 1 emissions refer to direct emissions that occur "from sources that are controlled or owned by an organization," such as the emissions from combustion in boilers or car exhausts (US EPA). At UConn, scope 1 emissions data include the following:

- Animal Husbandry

- Fertilizer (Farm, Research Farm, Athletics, Outsourced)

- Stationary Fuels

- Motor Pool

- Refrigerants

- CoGen Efficiencies

Scope 2: Indirect Energy Usage

Scope 2 emissions refer to indirect emissions "associated with the purchase of electricity, steam, heat, or cooling," (US EPA). These emissions do not occur on site at the university, but still need to be accounted for because they are a result of UConn's energy usage. The only Scope 2 metric for UConn is purchased electricity.

Scope 3: Other Indirect Emissions

Scope 3 emissions account for much of the GHG emissions on campus; they are "the result of activities from assets not owned or controlled by the reporting organization, but that the organization indirectly affects in its value chain," (US EPA). In different words, the scope 3 emissions at UConn are the scope 1 and 2 emissions of a different organization. Anything not included in the scope 1 and 2 emissions boundary is part of scope 3 emissions. Some examples of scope 3 emissions include business travel, employee commuting, transportation and distribution, and more. UConn Scope 3 metrics include:

- Commuting

- Floriculture Compost

- Paper

- Solid Waste

- Wastewater

2023 GHG Inventory

The OS Intern team is currently working on completing the GHG Inventory for 2023. Check back soon! Past emissions reports for UConn are available at the link below.

View UConn's Emissions Over the Years

Energy Efficiency and Conservation

The CAP established a goal of achieving a carbon neutral main campus by 2050, with several interim milestones, such as a 20% reduction in greenhouse gas (GHG) emissions (from a 2007 baseline year) by 2020 and 30% by 2025. We work collaboratively with the Utility Operations & Energy Management group in Facilities to achieve these goals, primarily through a variety of strategic energy conservation projects.

The University is well on its way toward meeting these GHG emissions reduction goals. As of 2017, a net reduction of 18,882 tons of GHG emissions from the 2007 baseline had already been achieved. Current estimates indicate that by 2020, emissions will be reduced by another 20,108 tons. Accounting for ongoing and proposed energy efficiency and clean energy projects, UConn is on pace to reduce annual emissions by a grand total of 32,600 tons by 2020. This represents a 21.4% reduction, saving almost 38 million kWh worth approximately $2.9M, despite considerable growth in enrollment and new buildings constructed since 2007.

Two especially impactful initiatives include the campus-wide re-lamping and steam line improvement projects. Project evaluation estimates show that retrofitting all interior and exterior lighting with LEDs will contribute nearly 40% of the carbon emissions reductions needed to meet the 2020 interim goal, with ongoing steam projects contributing 30%. Another 19% reduction will come from ESCO Phase I. Completed in 2017, this is an approximately 2,600 linear foot steam line replacement project, with associated energy conservation measures (ECMs) in seven campus buildings. In total, ESCO Phase I saves the University a projected $1.3M each year in utility costs.

Additional energy efficiency and GHG reduction projects underway include increasing the percentage of green (EV and hybrid) vehicles in UConn’s fleet and implementing other ECMs, such as the installation of variable frequency drives (VFDs) on motorized equipment that controls HVAC systems.

UConn’s 2020 Vision Plan includes energy efficiency-related metrics, like completing the SLED project by 2020 and reducing Energy Use Intensity (EUI) by 20% in buildings served by the Central Utility Plant.

Learn more about energy conservation from Facilities Operations

Co-Generation Plant

UConn’s state-of-the-art Co-Generation Facility opened in February 2006, replacing several oil-fired utility boilers and enabling the University to meet its own energy needs at the main campus. Co-Generation is defined as the sequential production of both electrical or mechanical energy and useful thermal energy from a single energy source. This allows over 80% of the fuel energy to be harnessed, versus 33% from a conventional electric power plant.

The Co-Generation facility provides a two-fold reduction in emissions:

- Natural gas, a cleaner burning fuel, is used by the facility to generate electricity and steam for heating and evaporative cooling.

- Also, the inclusion of steam production in the process removes the need to construct separate steam-production facilities that would burn their own fuel and have their own emissions.

Most power plants on the electric grid are considerably less efficient than cogeneration facilities because they do not capture and utilize the steam for heating and cooling. Also, “distributed generation,” like UConn’s 25 MW Co-Generation facility, prevents the efficiency loss and congestion that occurs during transmission and distribution of electricity from the point of generation to distant electricity customers.

Due to these features, the UConn Co-Generation facility reduces carbon dioxide (greenhouse gas) emissions by an estimated 30,000 tons each year versus emissions from fossil-fueled power plants serving the regional electric grid.

Learn more about the Co-Generation Plant from Facilities Operations

Alternative Energy Sources

The University of Connecticut commissioned a fuel cell power plant on its Depot Campus in April, 2012, that will supply the campus with clean and efficient energy, cooling, and heating for years to come. The installation of a UTC Power PureCell system is one of many steps made by UConn to reduce its carbon footprint and build a sustainable community. The fuel cell installation was made possible through a federal stimulus grant from Connecticut's Clean Energy Finance and Investment Authority.

The 400kW fuel cell will provide energy to UConn's research labs and offices, including those working on advancing fuel cell and microgrid technology at UConn's Center for Clean Energy Engineering. The PureCell system is an energy delivery solution that combines hydrogen fuel and oxygen from the air electrochemically (without combustion) to produce electricity, heat, and water. The new power plant will serve as a demonstration model and teaching tool for UConn students, helping them better understand the technology and benefits behind advanced microgrid energy systems that can deliver clean, reliable energy while protecting the environment.

By generating and using power on-site with a PureCell system, UConn will prevent the release of more than 831 metric tons of carbon dioxide annually, which is the equivalent to planting more than 192 acres of trees. The reduction in nitrogen oxide emissions compared to a conventional power plant is equal to the environmental benefit of removing more than 110 cars from the road. In addition to the reduction in greenhouse gas emissions, the PureCell system saves nearly 3.9 million gallons of water each year.

Click here to read the full article about the Fuel Cell from UConn Today.

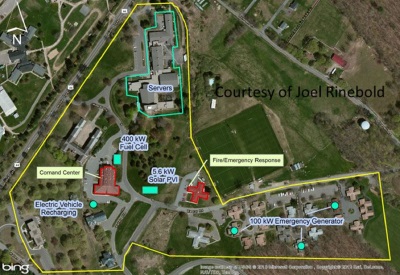

UConn is currently pursuing the creation of a Microgrid on Depot campus. The plan is currently undergoing the approval process and the technical feasibility evaluation was recently passed.pdf.pdf by the Department of Energy and Environmental Protection. The Microgrid proposal has also been given the formal support.pdf of the Town of Mansfield. In addition, the University of Connecticut was awarded a $2.14 million dollar grant as part of the Connecticut Department of Energy and Environmental Protection $18 million dollar Microgrid Pilot Program. This program was designed to research and document the effectiveness of microgrid energy systems in supporting and protecting critical needs systems during times of extended grid outages.

With the implementation of the new microgrid system, the fuel cell would be able to function at full capacity even despite the grid outage. This will allow the University’s critical needs facilities (fire/emergency response, command center, data servers, etc.) to keep functioning when they are needed most. Overall this project will bolster the university’s emergency response capabilities while providing significant research benefits on the practicality and effectiveness of microgrid systems for the state of Connecticut. Beyond emergency response, the microgrid will harden UConn's energy infrastructure, modernize the state’s electric grid, promote renewable energy projects, and support energy efficiency in the state of Connecticut.

Click here to read about Microgrid Progress and Emergency Response from UConn Today.